Companies Who Trust Us

What is a Lean Management System?

The Lean Management System is a cutting-edge Augmented Intelligence Platform that revolutionizes Lean methodology. At its core is the Interactive Kaizen Project Guide, acting as a virtual Master Black Belt to navigate complex problems using Lean principles and the DMAIC framework. Complemented by on-demand Lean Training and dynamic project dashboards, it offers comprehensive insights and skill enhancement. Our proprietary LeanBot further enriches this platform, providing instant assistance and recommendations. This system is not just a tool, but a transformative force for operational excellence and continuous improvement.

Benefits of the Lean Management System

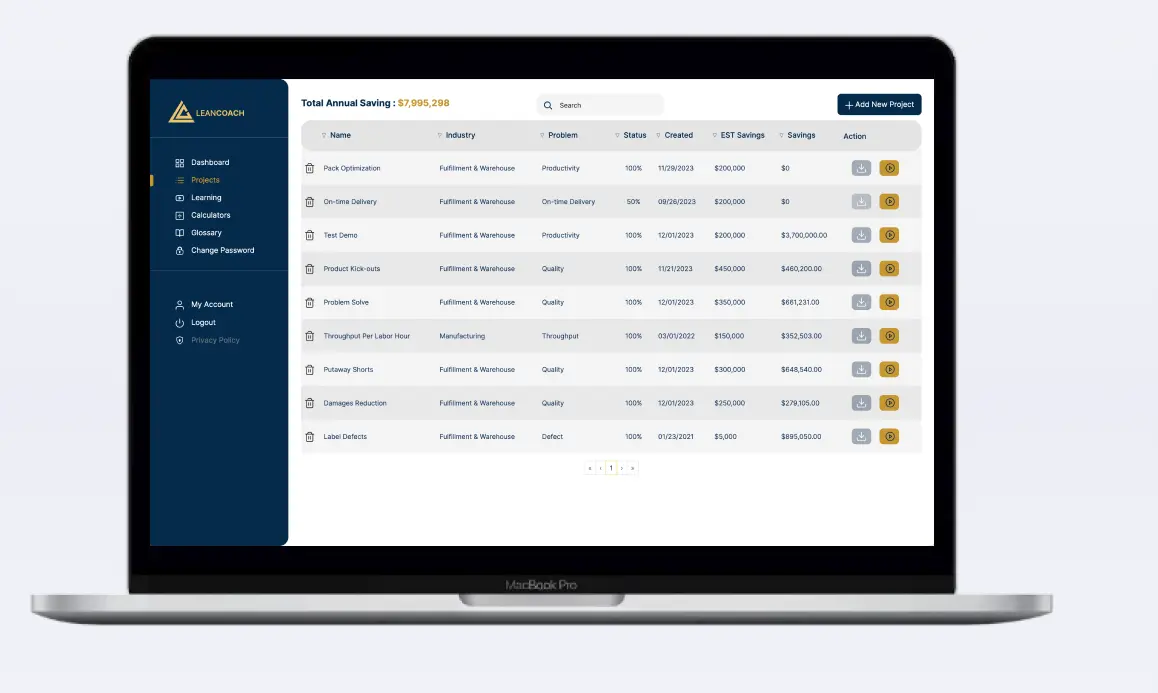

Kaizen Project Guide & LeanBot

The Interactive Kaizen Project Guide, a cornerstone of our Lean Management System, stands as a pioneering digital mentor in the Lean Methodology, guiding users through solving complex problems with precision and insight. This tool is enhanced by the LeanBot, our proprietary feature that offers immediate assistance, insights, and recommendations. The LeanBot is more than just a support tool; it's an intelligent companion, helping users to apply Lean principles effectively and efficiently, fostering a deeper understanding and practical application of Lean concepts.

Try It NowDynamic Dashboards

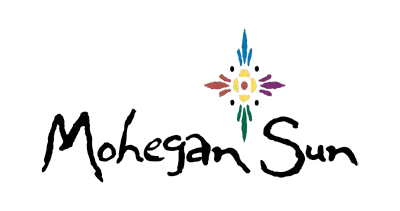

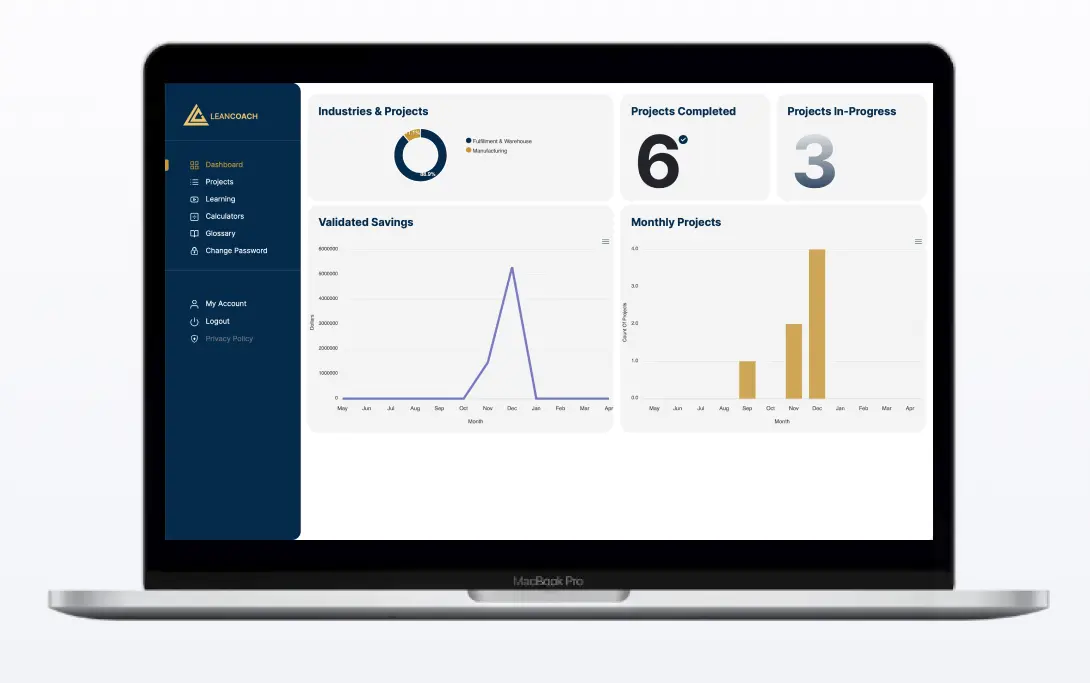

Our dynamic project dashboards are pivotal in providing real-time analytics and insights essential for tracking progress and guiding decision-making in Lean initiatives. These dashboards act as an operational hub, offering clear, detailed views of project trajectories and milestones. A key benefit of utilizing our dashboards is the significant increase in the continuous improvement project completion rate. By providing comprehensive data and actionable insights, these dashboards empower teams to streamline their processes, enhance productivity, and achieve their continuous improvement goals more rapidly and effectively.

Get 30 Days FREE

On-Demand Lean Management Training

At the heart of Lean Coach Lean Management System is an extensive array of on-demand Lean Management Training modules. These modules are expertly crafted to provide comprehensive learning experiences, addressing a wide spectrum of topics to cater to various expertise levels and organizational requirements. This ensures that every team member is equipped with essential knowledge and practical skills to effectively implement Lean principles. The platform’s emphasis is on facilitating immediate, impactful learning for operational excellence. Additionally, as a key highlight, we offer Lean Six Sigma virtual certifications, complementing our robust learning modules with opportunities for formal qualification and recognition in Lean Coach Consulting.

Key Features

Strategic recommendations based on real-time data and objectives

On-demand video instruction

Dashboard to manage continuous improvement projects

Customized tools, calculators, and templates

Standardized

workflows

Lean Six Sigma Yellow Belt Certification

Detailed analytical insights and custom data tools

Financial summaries, including expected annual savings

Pricing

Individual Account

$0/ First month FREE

Lean Coach® Strategies

The focal point of every Lean organization is stability. Without it, an organization implodes with the slightest variation. Without stability in our workforce, processes, equipment, quality, safety, supply chain, and customer demand, an organization falls into chaos and will eventually fail. Each of the eight core principles coordinates with one another and helps create the needed stability. These principles include:

People

People are our Greatest Assets The mindset of empowering and engaging with employees at all levels to solve problems, make decisions, identify problems and build mutual trust and respect.

Standardized Work

Standardized Work Identify the most efficient way of completing a task, designed around human movement, and designed with a mechanism to ensure it is repeatable and reproducible. Without a standard, you will never be able to measure progress.

Six Sigma

The use of statistical analysis identifies variation within the process and implements multiple tools to monitor and control the process. As we enter Industry 4.0, data analytics is becoming a necessity rather than a competitive advantage. Our goal is to develop you into becoming a data-driven leader.

Just-in-Time

An inventory strategy organizations employ to increase their delivery speed and reduce inventory and space costs by receiving goods only as they are needed in the production process. When established, a Just-in-Time strategy may be the source of competitive advantage.

Scrum

A lean method for project management that streamlines communication, collaboration, innovation, and continuous improvement. Also known as Agile, Scrum will provide you and your team with the framework to increase productivity anywhere from 200 to 800 percent.

Autonomation

Autonomation with a human touch. The principle is to transfer human intelligence into a machine. Autonomation prevents the production of defects, eliminates over-production, and allows anomalies to be investigated immediately at the point of error.

Theory of Constraints

Introduce systems thinking focused on maximizing flow by improving the bottleneck and Throughput Accounting to ensure the organization’s metrics are aligned with their financial goals.

Go and See

Derived from the Japanese word, Genchi Genbutsu, meaning “Go and observe, or go and see” at the place where value is created. This principle creates a shop-floor focus by encouraging leaders to close their computers or leave their desks and engage with the team at the problem’s source.

Without an indication of continuous improvement in your organization, these principles and strategies are usually all-for-not. As such, the team at Lean Coach® is continually looking for ways to apply and improve on these eight principles by eliminating waste, and bringing a culture (we like to call it a “Lean” Culture) of continuous improvements to your organization that are palpable and meaningful.

Pricing

Individual Account

$0/ First month FREE

Success Stories:

Transformation with

the Lean Management System

Fill Out the Form For Your FREE First Month

You will not be charged until your one-month free trial has concluded